Aluminum alloys, with their lightweight, high-strength, and cost-effective advantages, have become the mainstream choice for mid-to-high-end smartphone frames. In the consumer electronics industry, which is pursuing extreme thinness, complex designs, and sustainable development, traditional smartphone case manufacturing processes are facing severe challenges. Traditional smartphone cases are manufactured using extrusion molding and CNC machining, primarily employing aluminum alloys from the 6 series (such as 6061) due to their ease of forming.However, for higher-strength aluminum alloys such as the 2 series (e.g., 2024), traditional processes are difficult to apply due to their tendency to crack during high-temperature extrusion, resulting in high processing difficulties and low yield rates.

Enigma has broken new ground with DED technology, redefining the logic of aluminum alloy manufacturing and overcoming the limitations of this material. By precisely controlling the arc melting of metal wire and depositing it layer by layer, it can perfectly prepare difficult-to-process materials such as high-strength 2-series aluminum alloys, which are then machined to final precision using efficient CNC processing. This provides a new possibility for mobile phone protection solutions that pursue extreme lightweight and high strength.

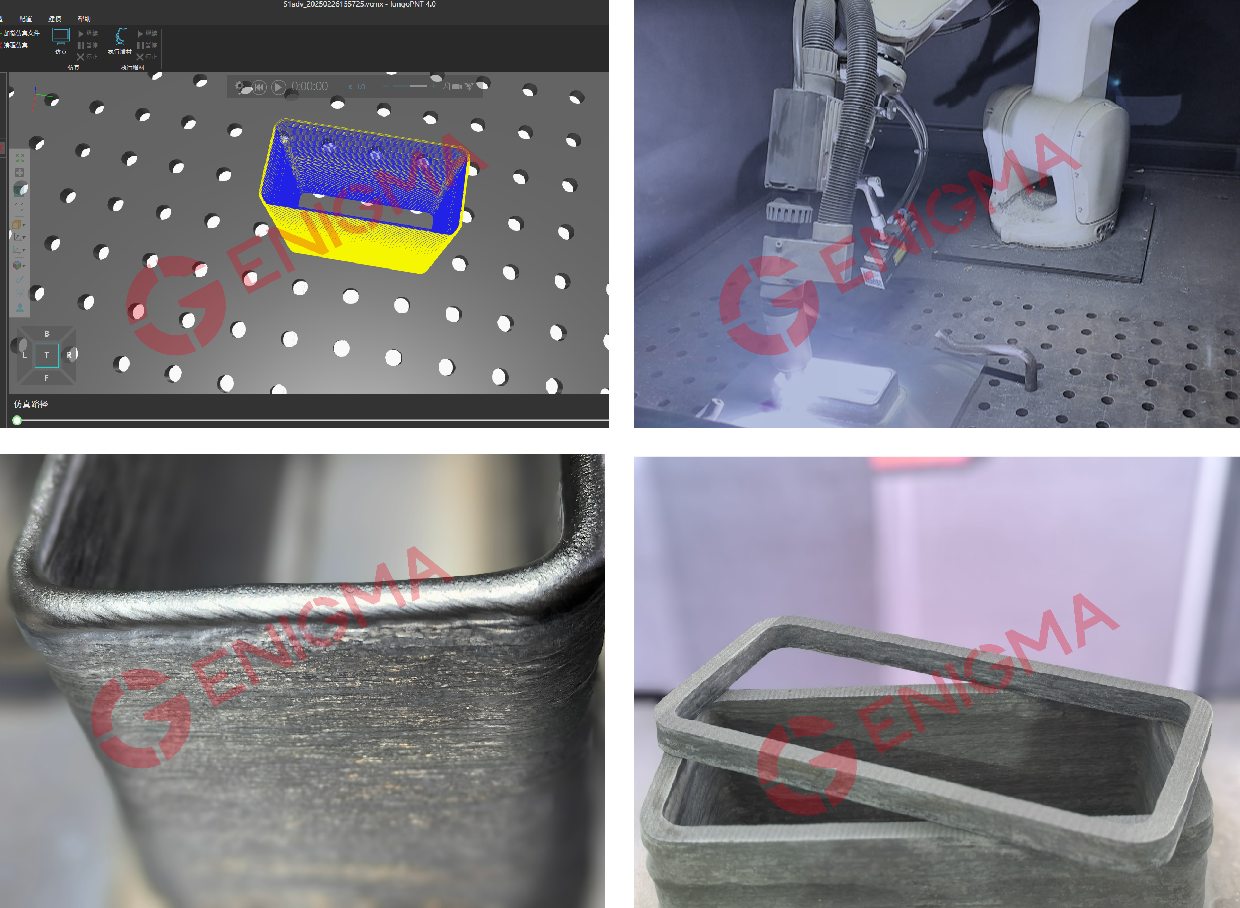

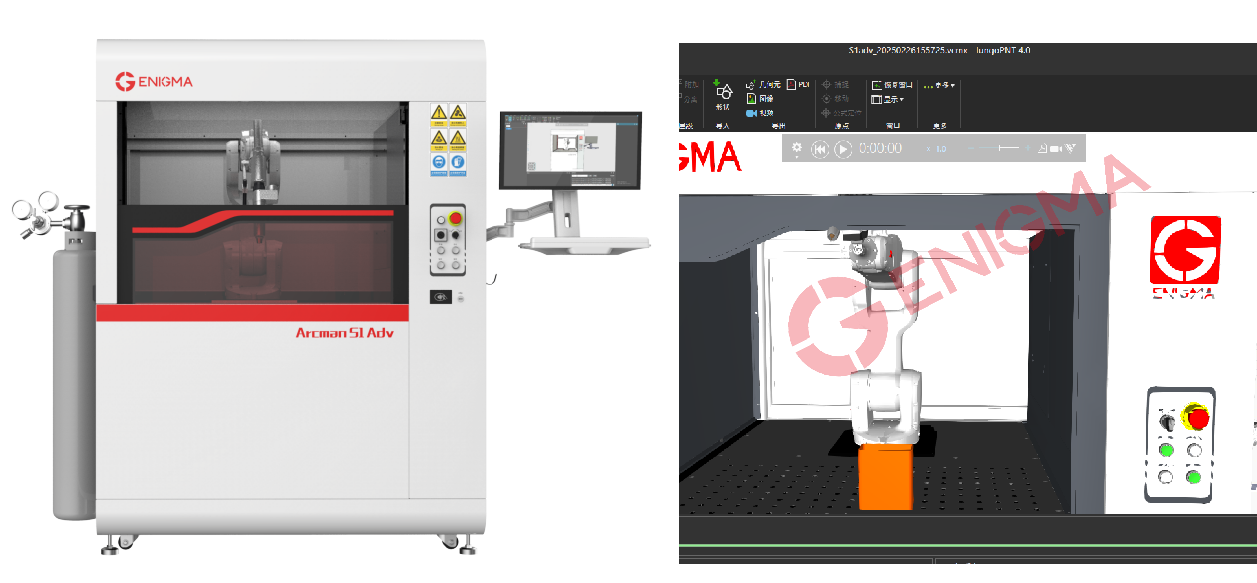

Digitalization and Intelligence-Driven Deposition Process Innovation: IungoPNT's additive manufacturing-specific software intelligently optimizes additive manufacturing processes, including path optimization, arc start/stop optimization, and speed optimization, to minimize the occurrence of printing defects. Through highly accurate layout simulation and dynamic path simulation, users can view the process in real-time with 360° dynamic speed adjustment, enabling pre-verification of accessibility, joint constraints, singular points, and collision risks.By embedding a compensation allowance of 0.1-0.2mm into the path, combined with “contour-fill” zone printing (contour line accuracy ±0.03mm), the dimensional error of aluminum alloy blanks is ≤±0.3mm, representing a 50% improvement over traditional DED processes.Additionally, it supports ultra-thin wall thickness and lightweight structure printing, providing efficient solutions for critical components such as hinges in foldable smartphones.

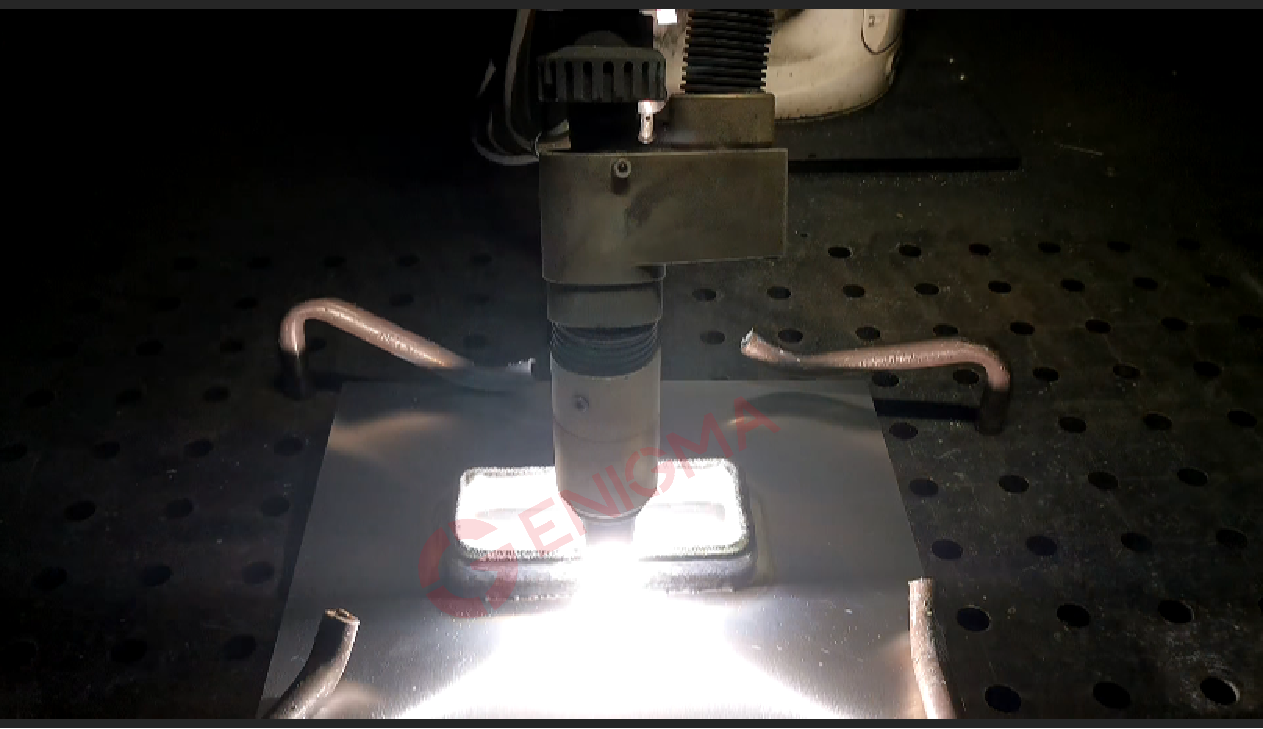

Aluminum alloy mobile phone frame printing process with molten pool monitoring screen

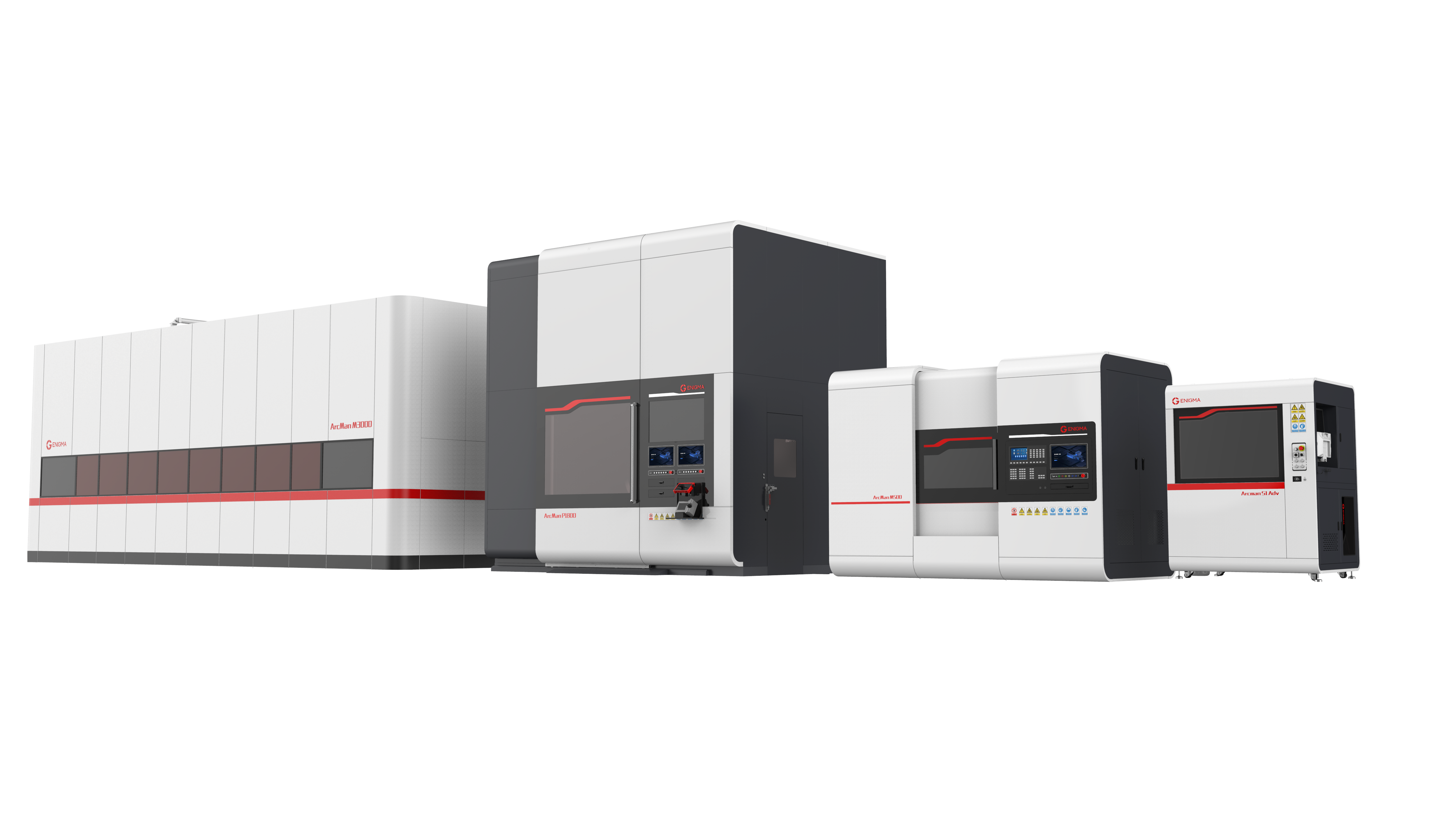

As a global leader in DED, Enigma has developed its proprietary ArcMan series of DED equipment. Through deep integration of materials, processes, and equipment, the ArcMan series has achieved a revolutionary breakthrough in the manufacturing of aluminum alloy mobile phone frames.

ArcMan S1 lightweight intelligent DED system, equipped with IungoPNT software specifically developed for DED, features proprietary slicing methods and fill path planning optimized for DED, enabling graphically optimized additive quality control. The system achieves high forming efficiency with a maximum forming efficiency of 1085 cm³/h using the built-in process library parameters. The equipment has a small footprint,with a total weight of just 1 ton, allowing operators to easily move the equipment to the desired operating position and secure it in place. It offers advantages such as intelligence, high quality, high efficiency, and convenience, providing a fundamental guarantee for the mass production of aluminum alloy smartphone frames.

Through years of continuous innovation in wire DED technology, Enigma has redefined the manufacturing paradigm for aluminum alloy mobile phone frames. From the skies to the palm of your hand, Enigma has injected new momentum into the application of aluminum alloys in consumer electronics—lighter than feathers, stronger than steel, now both are possible.

Hot News

Hot News2025-06-30

2025-07-04

2025-07-01