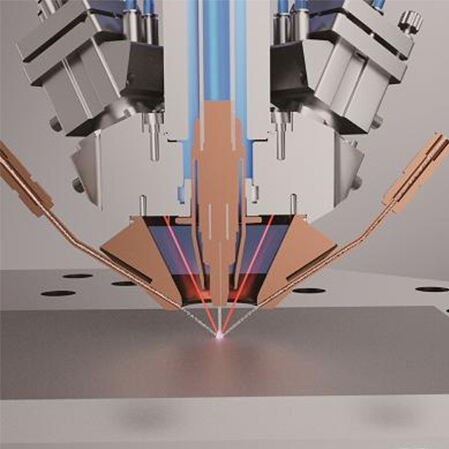

Coaxial Multi-Laser Hybrid Technology

The coaxial multi-laser hybrid additive manufacturing system integrates six fully independent laser modules with an arc heat source, with six-channel powder/wire feeding systems. This achieves triple hybridization: multi-wavelength laser fusion, laser-arc synergy, and wire-powder combination. The system enables cutting-edge DED applications including functionally graded materials, in-situ alloying additive manufacturing, high-throughput material development, and microstructure control. It simultaneously addresses industrial requirements by enhancing material compatibility, deposition efficiency, part accuracy, performance, and geometric complexity in DED engineering applications.

| CML-Hybrid-1500DF-ARC | |||

| Rated Power Output | 1500W | Maximum wire heating current | undefined |

| Number of Lasers | 6, individually controlled | Deposition efficiency | undefined |

| Powder Feed Channels | 6, individually controlled | Deposition head dimensions | 210 x 262 x 730 mm |

| AM Process | CML/CML-Hybrid | Deposition head weight | undefined |

| Laser Wavelengths | 915 nm x 3 + 450 nm x 3 | Wire diameter | 0.8 - 2.0 mm |

| Spot Diameter | Φ 2 mm | Powder particle size | 20 - 300 μm |

01 Multi-Wavelength Coaxial Laser

• Fully independently controlled six laser modules enable multi-wavelength coaxial hybrid laser output.

• By combining typical wavelengths (e.g., red-blue hybrid), it broadens material compatibility, enhances absorption for reflective metals and remains cost-effective.

02 Laser-Arc Coaxial Hybrid

• Independently controlled laser-arc hybrid heat source enhances additive efficiency, component performance, and structural complexity.

• By alternating between the two processes, it combines laser precision with arc deposition efficiency, making it ideal for large-scale, geometrically complex metal additive manufacturing while ensuring high productivity and superior quality.

03 Wire-Powder Coaxial Hybrid

• The system combines wire feeding with six fully independent powder delivery channels to achieve independently controlled simultaneous wire-powder additive manufacturing.

• It enables highly flexible material ratio adjustment for rapid development of variable-composition gradient materials, nanoparticle-reinforced materials, and meets the high-throughput preparation requirements for new material development.