As an emerging additive manufacturing technology, DED (Direct Electric Discharge) has demonstrated unique advantages in the manufacturing of Inconel 625 alloy due to its high efficiency, low cost, and large-scale forming capabilities. However, the traditional DED process often results in a columnar crystalline structure with a distinct <001> orientation, which makes it challenging to achieve both ideal strength and ductility in the material.

I. Research Background and Significance

Recent studies have found that increasing line energy density (LED) can effectively improve the performance of Inconel 625 alloy by transforming columnar grains into near-equiaxed grains; however, the specific mechanism of the role of print path switching remains unclear.Additionally, the unique interlayer interface characteristics of additive manufacturing significantly influence material mechanical properties, particularly at high temperatures, where they can lead to interface strain concentration and premature failure. Therefore, investigating the influence mechanisms of interlayer interfaces at different temperatures is of great value for optimizing processes and enhancing material performance.

Based on the aforementioned research background, Enigma collaborated with a team from Technology and NOVA University Lisbon in Portugal to publish their latest research findings in Materials Research Letters titled “Enhanced mechanical properties and deformation mechanisms in DED Inconel 625 via printing path switching,” systematically exploring the influence of printing path design on material microstructure and mechanical properties.

Source [1]

II. Experimental Methods

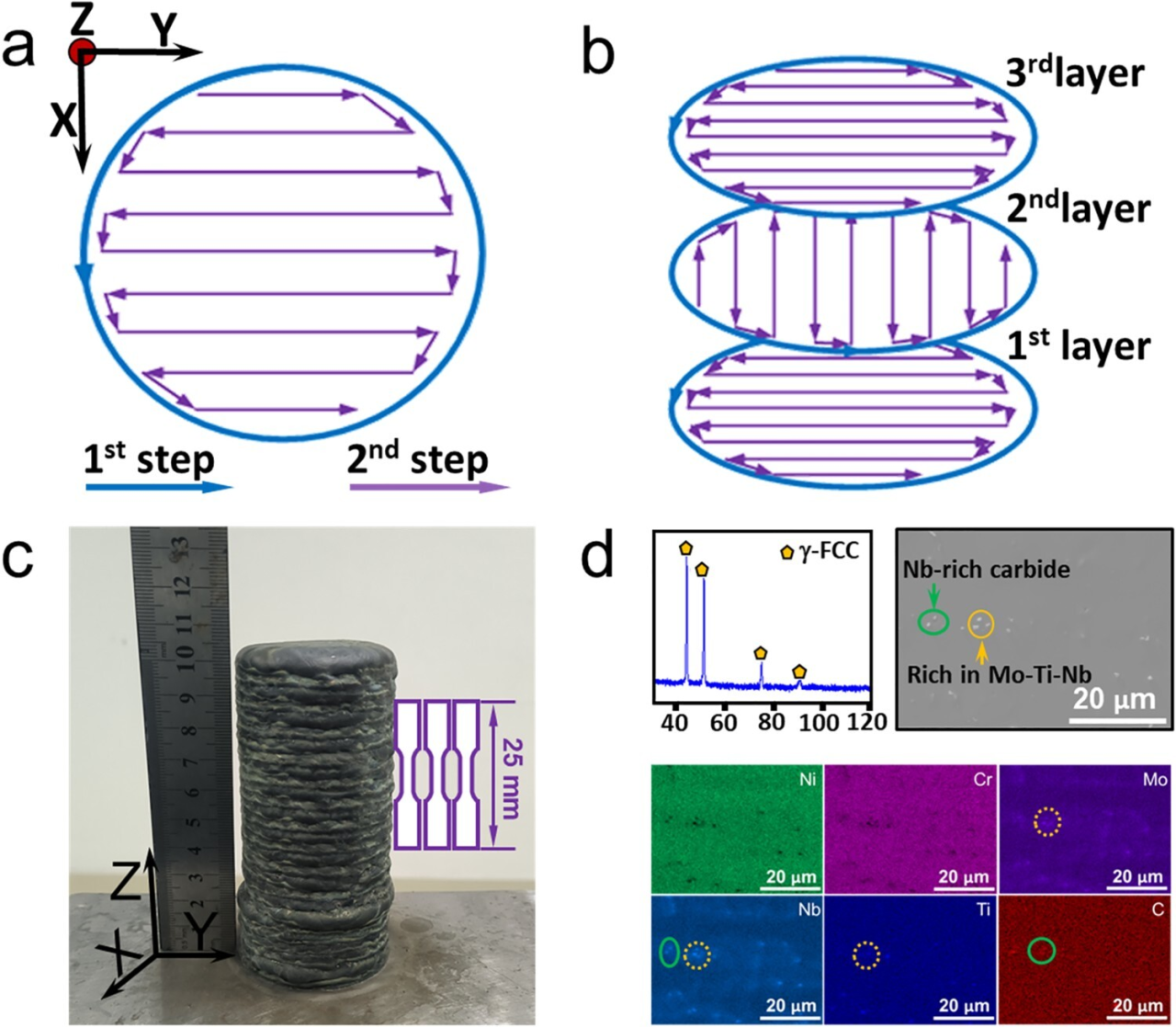

This study employed Cold Metal Transfer (CMT) DED technology to fabricate Inconel 625 alloy samples under a protective atmosphere of 70% Ar + 30% He mixed gas.To ensure the reliability of the experimental results, the research team optimized the key process parameters: current 116 A, wire feeding speed 4.6 m/min, and line energy density 140 J/mm. A layer-to-layer 90° rotation path strategy was adopted to prepare cylindrical specimens with a diameter of 50 mm and a length of 100 mm.

Source [1]

To comprehensively characterize the material properties, a multi-scale analysis method was adopted: microstructural evolution was analyzed using XRD, OM, SEM-EBSD, and TEM systems; mechanical properties were evaluated using microhardness testing and tensile experiments at room temperature and high temperatures (400-850°C).

III. Results and Discussion

3.1 Microstructural characteristics

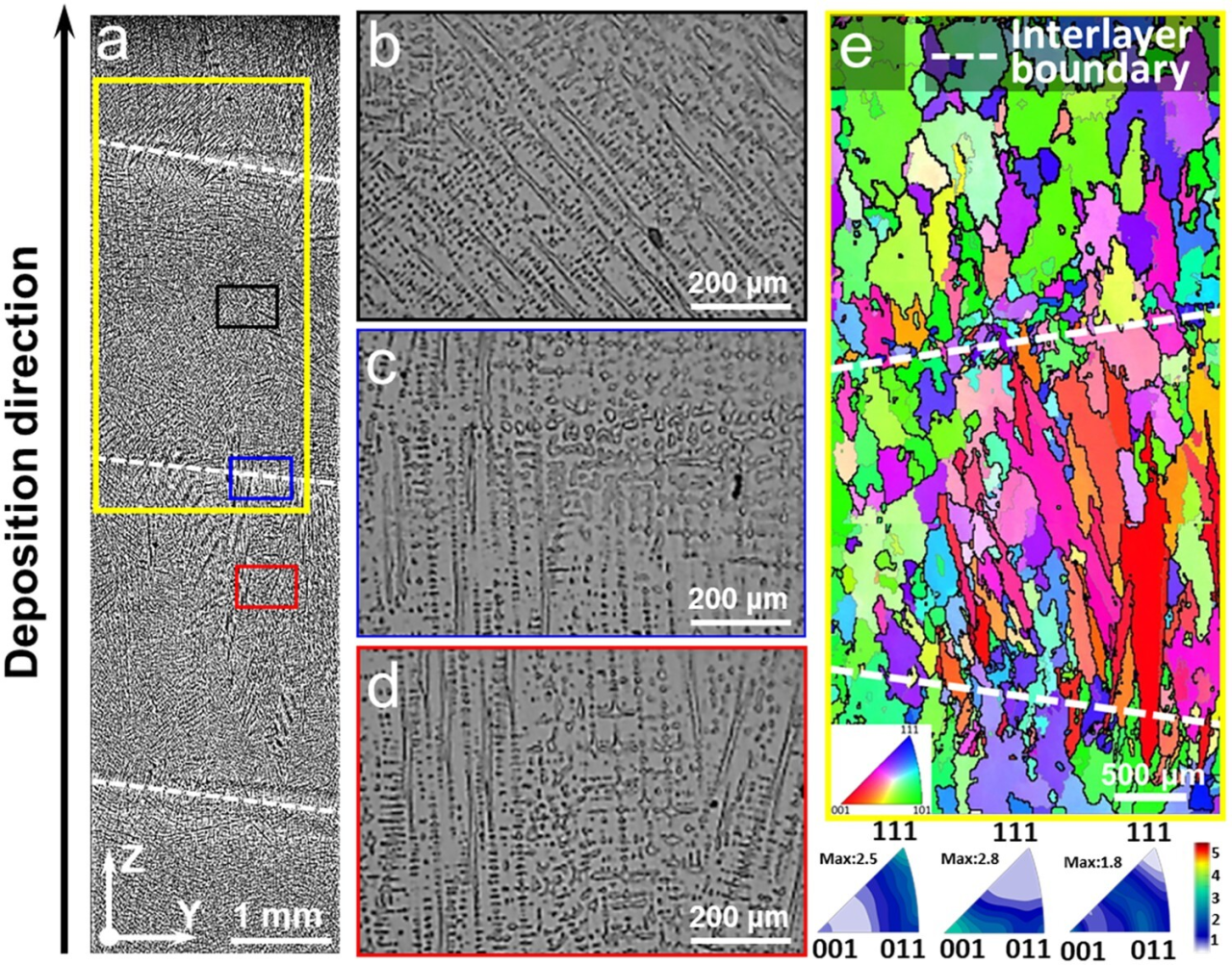

Microstructural analysis revealed the significant influence of the printing path design. Compared with the traditional 0° path samples, the samples prepared using the 90° path switching exhibited unique near-isotropic crystal characteristics: the average grain length was 527 ± 5 μm, the width was 172 ± 7 μm (aspect ratio 3.06), and fine-grained regions (37 ± 2 μm) formed at the layer interfaces.XRD analysis confirmed that the samples exhibit a single-phase face-centered cubic structure.

Source [1]

Research has confirmed that high LED combined with path switching can effectively reduce the melt pool temperature gradient, suppress columnar crystal epitaxial growth, and promote equiaxed crystal formation by increasing the remelting depth and providing new nucleation sites, thereby optimizing the microstructure of the material. This process combination provides an effective means of achieving the transformation from columnar crystals to equiaxed crystals.

3.2 Mechanical properties at room temperature

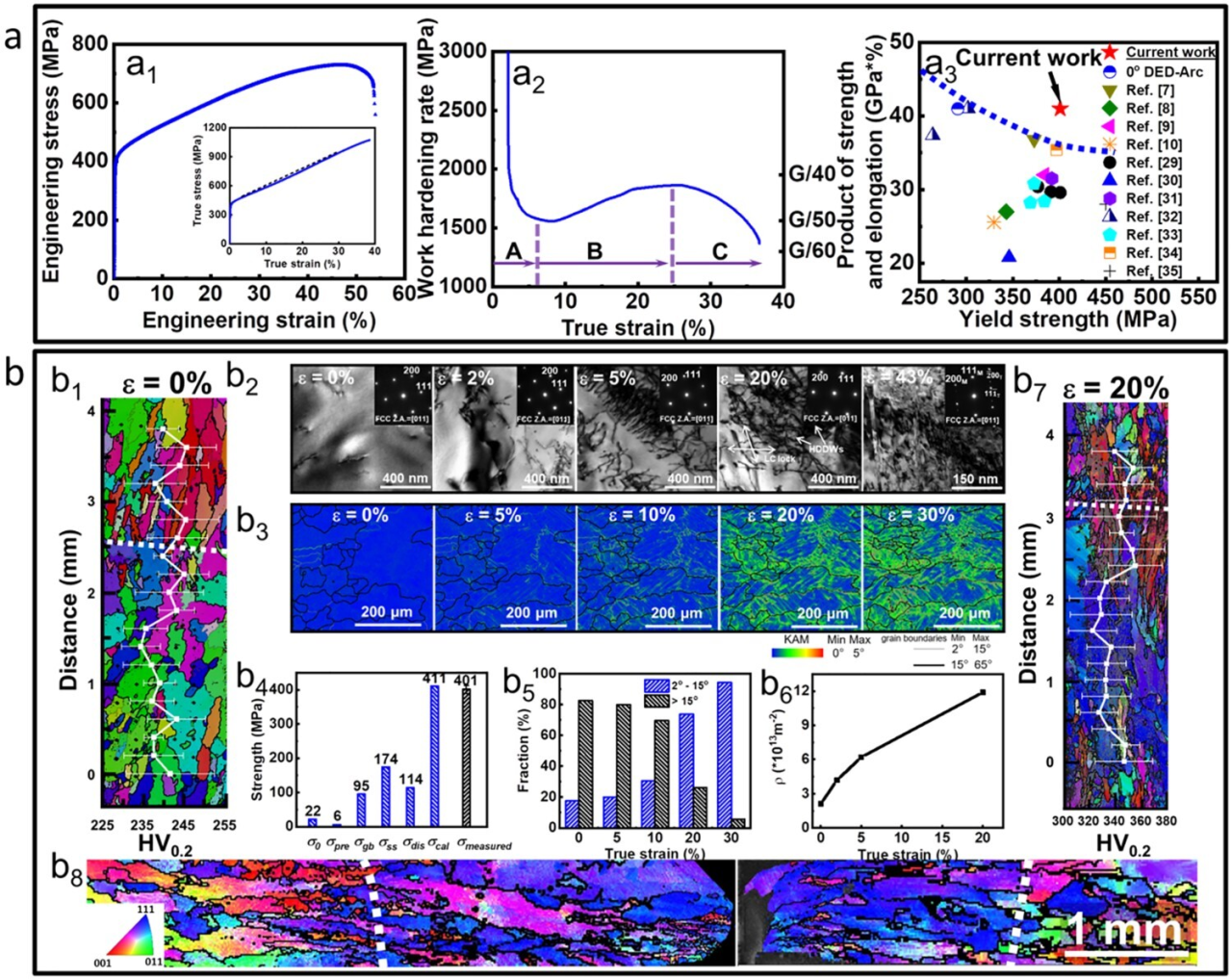

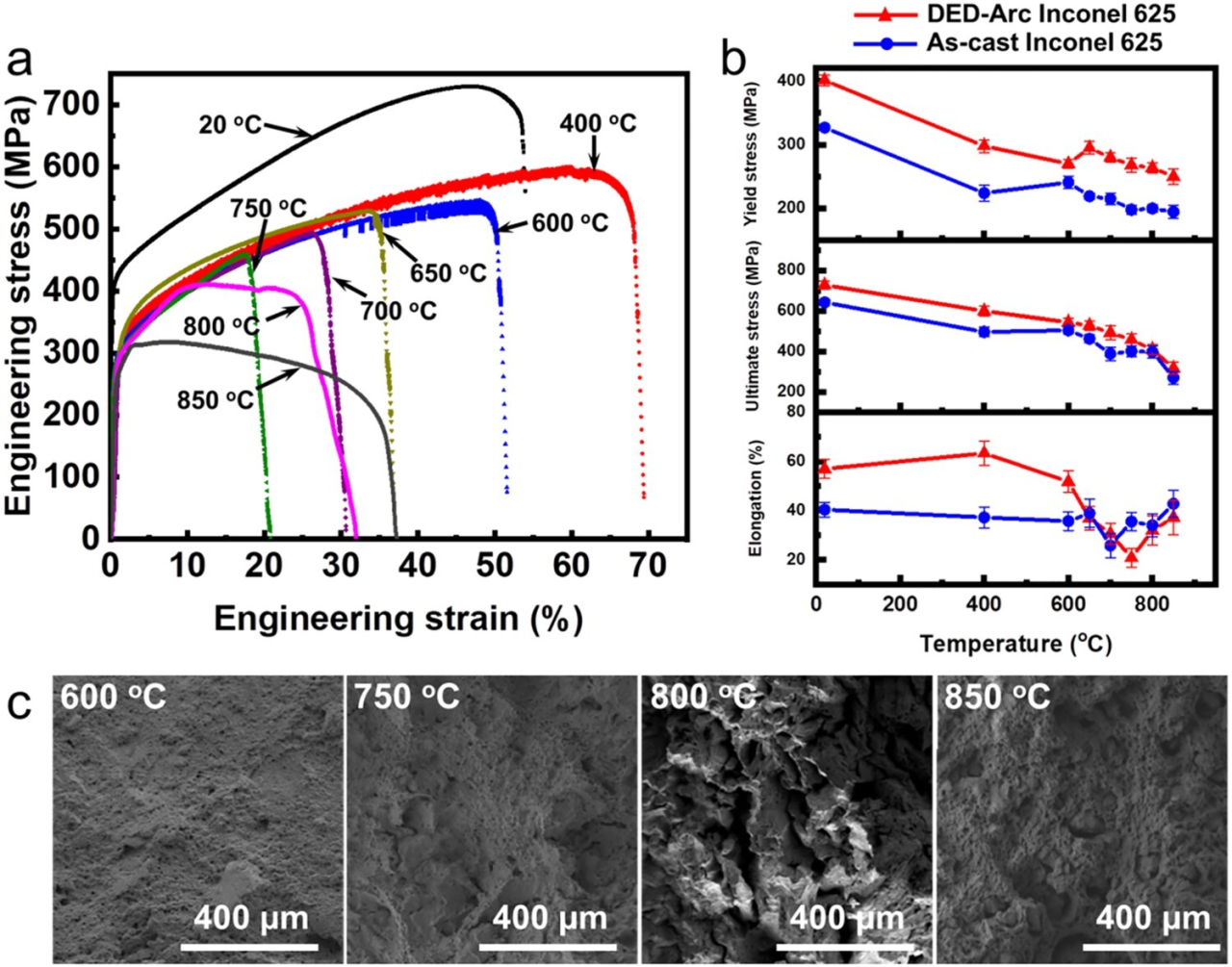

Room temperature mechanical property tests indicate that Inconel 625 samples prepared using a 90° printing path exhibit excellent strength-ductility matching, with a yield strength of 401 ± 12 MPa, tensile strength of 724 ± 5 MPa, and elongation of 57 ± 5%.The material exhibits typical three-stage work hardening behavior, particularly showing enhanced work hardening capability in the 8–25% strain range, resulting in a high plasticity-strength product of 41.3 GPa*%, significantly outperforming traditional hot-rolled alloys (32.1 GPa*%).

Source [1]

Microstructural analysis reveals that near-equiaxed samples exhibit larger grain sizes (232 ± 16 μm vs. hot-rolled samples < 130 μm), and their superior performance primarily stems from two factors: first, the key role of dislocation strengthening, and second, a unique deformation mechanism.Microscopic analysis revealed that during deformation, the material forms high-density dislocation walls and dislocation lock structures. These microstructural features effectively prevent dislocation movement, thereby enhancing material strength. More importantly, no stress concentration was observed at the interlayer interfaces, and fracture always occurred within the grain boundaries, confirming that the interfaces formed by the printing path do not affect material performance. It is this unique dislocation motion combined with intact interfaces that collectively confer the material's outstanding comprehensive properties.

3.3 High-temperature mechanical properties

High-temperature mechanical property testing has revealed the excellent high-temperature adaptability of near-isotropic Inconel 625 alloy. Research shows that within the wide temperature range of 400–850°C, the strength properties of this material consistently outperform those of traditional cast alloys.Notably, its elongation remains at a higher level below 700°C, with only a slight decrease observed after exceeding 700°C. Through fracture morphology analysis, the study observed distinct temperature-dependent fracture behavior transitions: at 600°C, the fracture exhibited typical intergranular ductile fracture characteristics, with the fracture surface showing uniformly distributed shallow ductile dimples;between 750°C and 800°C, the fracture mode transitions to intergranular fracture, exhibiting distinct brittle fracture characteristics; when the temperature reaches 850°C, the fracture surface exhibits a mixed fracture characteristic with both ductile dimples and brittle fracture planes.

Source [1]

IV. Conclusion

This study reveals the critical influence of print path design on the microstructure and properties of Inconel 625 alloy. By employing a printing strategy with high energy input combined with a 90° layer-to-layer rotation, the traditional columnar grain structure was successfully transformed into a uniform near-equiaxed grain structure. Through advanced microstructural analysis techniques, it was found that this unique structure exhibits distinctive dislocation motion patterns during deformation: not only planar slip occurs, but also high-density dislocation walls and special dislocation lock structures form.The synergistic interaction of these microstructural mechanisms endows the material with both excellent strength and ductility.

Notably, the interlayer fine-grain zones formed during printing not only did not weaken performance but actually enhanced it. Test results demonstrate that this optimized near-equiaxed crystal structure exhibits outstanding mechanical properties across a wide temperature range from room temperature to high temperatures. This discovery provides new process insights for high-performance additive manufacturing of critical components in aerospace and other fields, showcasing broad application prospects.

Paper link :

[1] https://doi.org/10.1080/21663831.2025.2476174

Hot News

Hot News2025-06-30

2025-07-04

2025-07-01