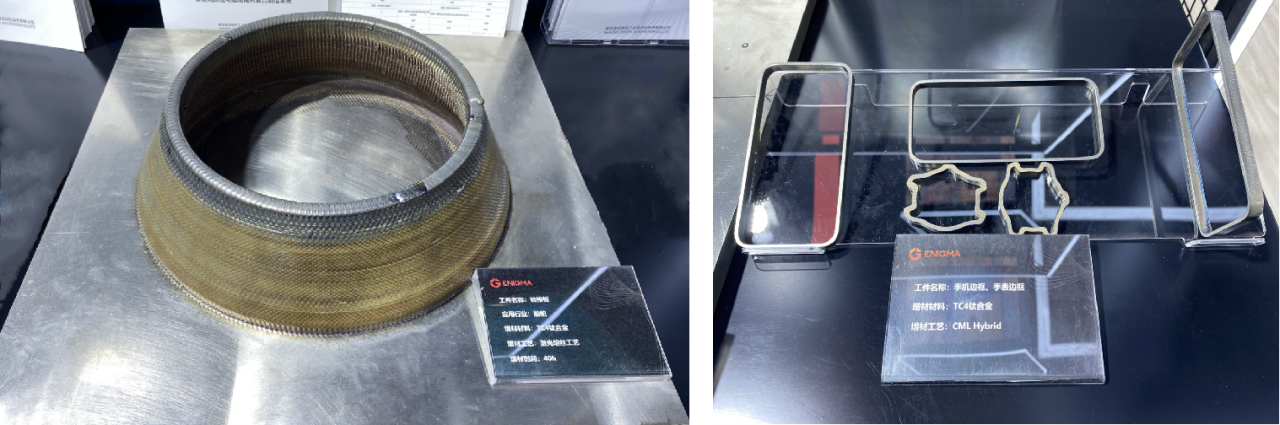

Titanium alloys, with their high strength, low density, corrosion resistance, and biocompatibility, have become a popular material in fields such as high-end equipment, and the 3C industry. However, traditional manufacturing processes (such as forging and casting) face challenges such as difficulty in forming complex structures, low material utilization, and high costs.Enigma's CML Hybrid multi-laser coaxial composite technology enables four-in-one composite processing, including multi-wavelength laser composite, laser-arc composite, wire-powder composite, and protective gas composite. This technology is suitable for variable composition gradient materials,in-situ alloying additive manufacturing, high-throughput material preparation, and microstructure control—key research directions in DED technology. Additionally, it meets the engineering application requirements of DED technology for enhancing additive material compatibility, additive manufacturing efficiency, component precision, performance, and complexity. The application of this technology is revolutionizing the production of titanium alloy components, providing a new solution for high-precision and high-performance application scenarios.

Technical principles

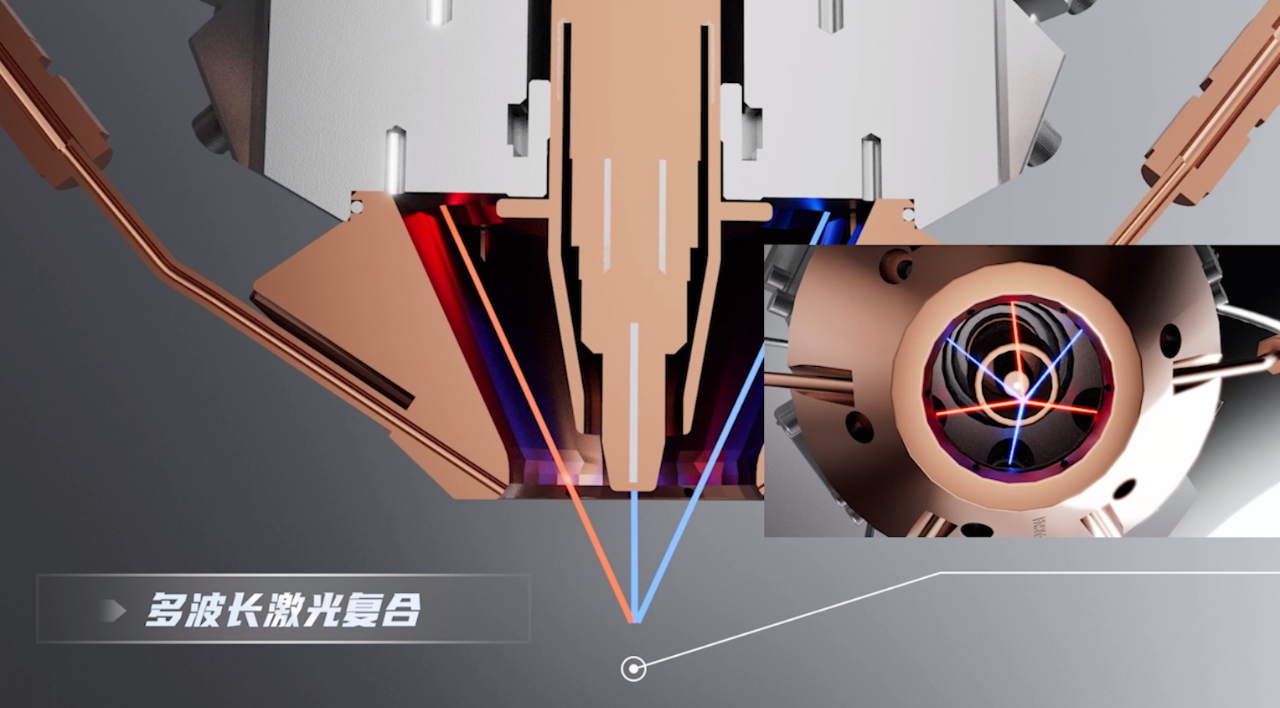

Multi-wavelength laser coaxial composite: Utilizing six independently controlled laser modules, this technology achieves multi-wavelength laser coaxial composite, significantly improving the absorption rate of lasers by highly reflective materials such as titanium alloys.

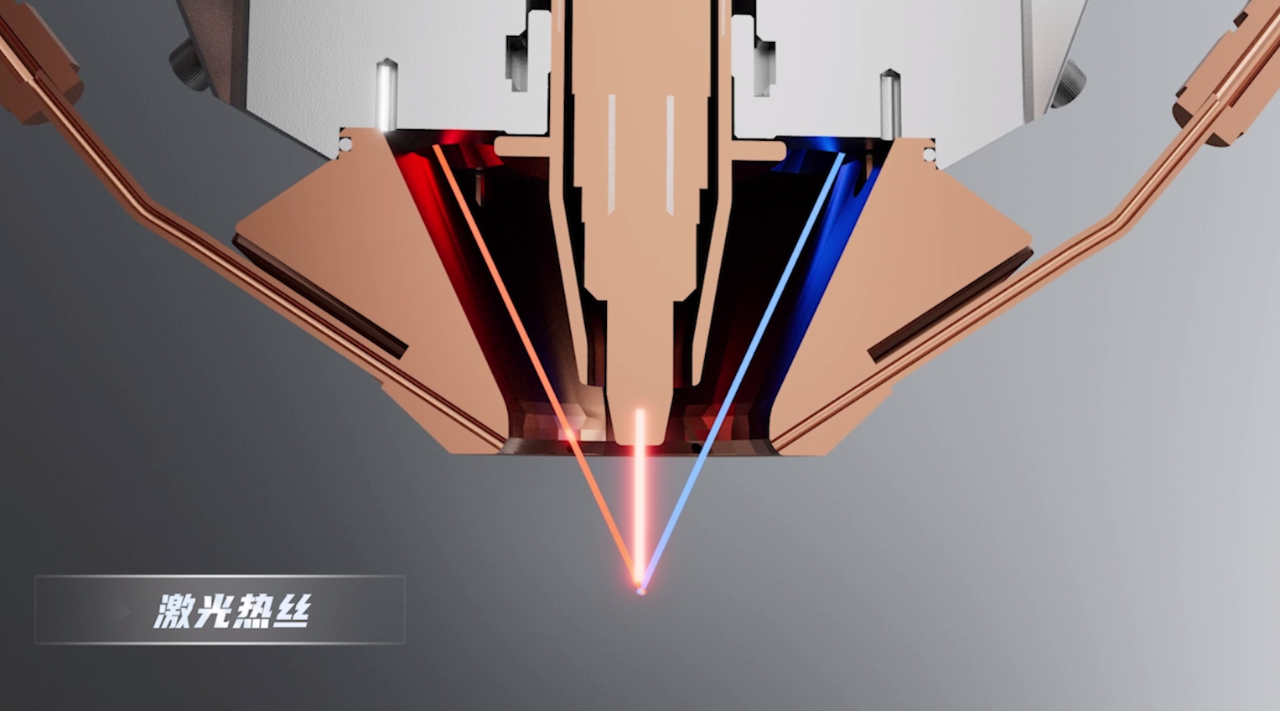

Laser-arc coaxial composite: Independently controllable laser-arc heat sources are used in combination, alternating between two processes. Arc energy and laser energy are dynamically matched in real time to form a synergistic effect of “laser preheating-arc cladding,” improving material additive manufacturing speed and precision.

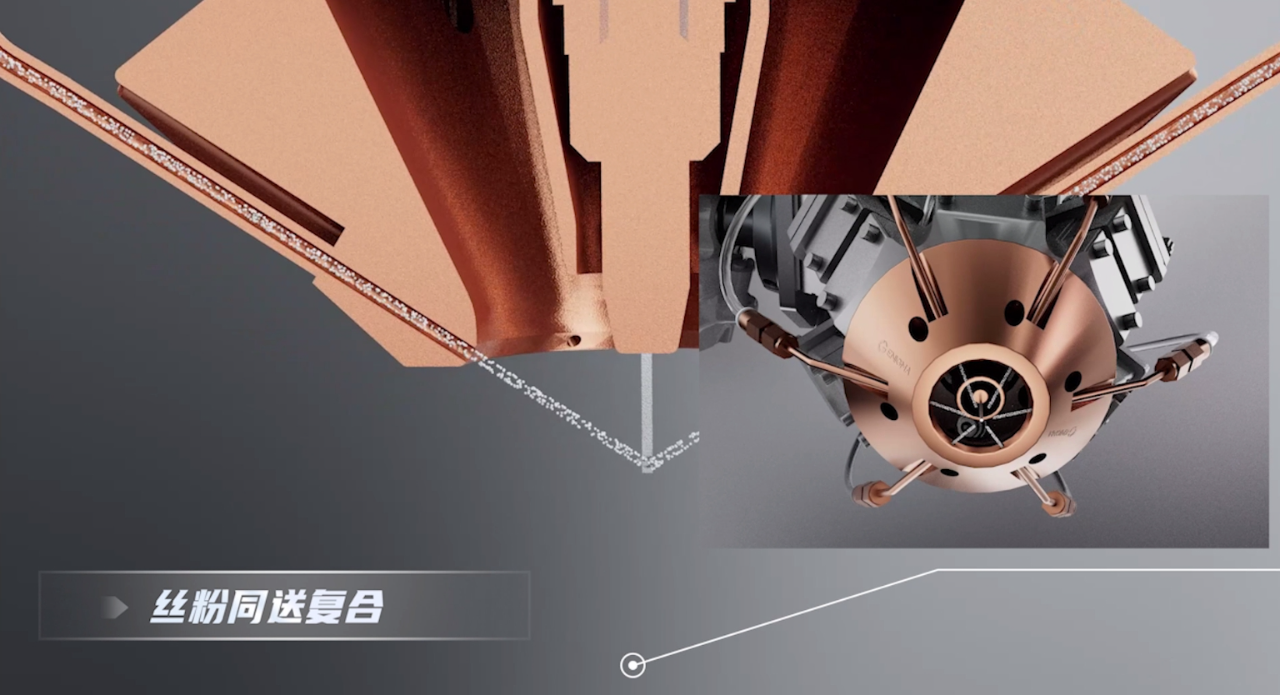

Coaxial composite of filament and powder: Supports simultaneous feeding of titanium alloy filament and powder, enabling gradient material printing.

Advantages of CML Hybrid Multi-Laser Coaxial Composite Technology in Titanium Alloy Manufacturing

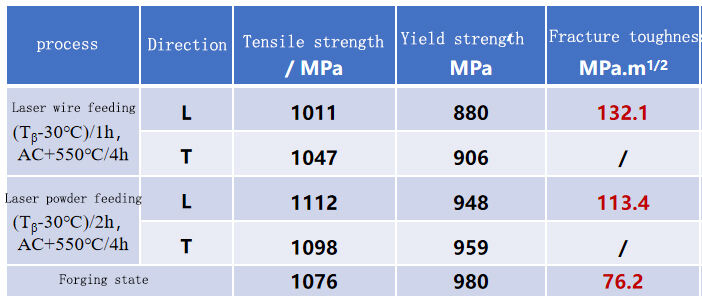

In terms of physical properties such as fracture toughness, TC11 titanium alloy specimens produced using laser additive manufacturing are significantly superior to those produced using traditional forging methods.

By comparing the performance of TC11 titanium alloy specimens produced using laser additive manufacturing and forging methods under room temperature conditions: In terms of strength, the specimens produced using laser additive manufacturing exhibit anisotropy but are comparable to forged specimens.In terms of fracture toughness, the laser-additive-manufactured specimens exhibit significantly higher fracture toughness than the forged specimens. Additionally, the fracture toughness of specimens produced using the wire feeding process is 17% higher than that of those produced using the powder feeding process.

In terms of forming efficiency and material utilization, laser wire feeding technology is superior to laser powder feeding technology.

The additive manufacturing efficiency of laser wire feeding is ≥1 kg/h, while that of powder feeding is 0.6 kg/h. Under the same laser power conditions, the deposition efficiency of wire feeding is approximately 40% higher than that of powder feeding. Additionally, the material utilization rate of the wire feeding process is approximately 100%, while that of the powder feeding process is approximately 60%. The wire feeding process achieves a 40% higher material utilization rate compared to the powder feeding process.

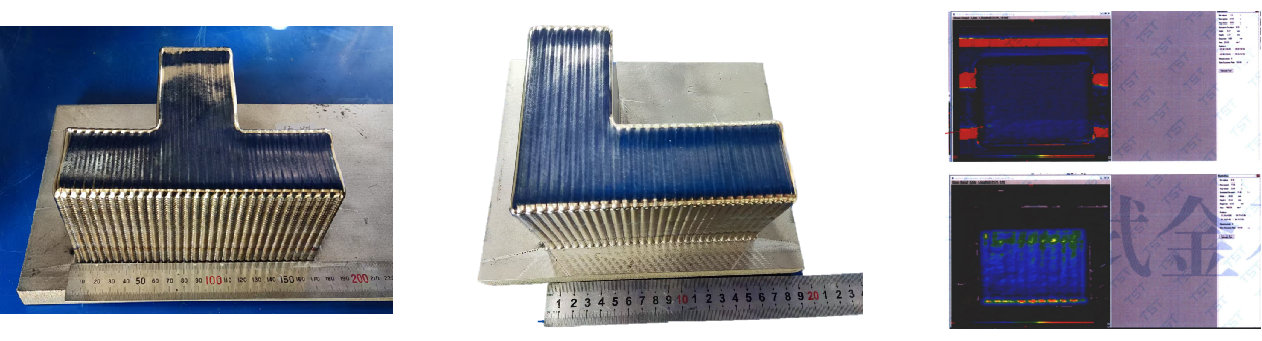

Wire feeding process test block

Powder deposition test block

The overall quality of the samples produced using CML Hybrid multi-laser coaxial composite technology meets the standard requirements.

The wall thickness error of TC11 titanium alloy specimens manufactured using laser wire feeding technology is within ±0.3 mm, with internal defects meeting the AAA level of ultrasonic testing for forgings, and mechanical properties meeting the requirements for components.

In addition, the use of additive manufacturing technology to produce titanium alloy components offers advantages such as lightweight design, high efficiency, and high precision.

Enigma provides a full range of solutions for titanium alloy components in various industries, including shipbuilding, 3C communications, and automobiles, from material process development to mass production. CML Hybrid multi-laser coaxial composite technology breaks through the challenges of precision, efficiency, and cost in titanium alloy additive manufacturing through the synergistic innovation of different processes, becoming a “disruptor” in the high-end manufacturing field and injecting new momentum into industrial manufacturing in various industries.

Hot News

Hot News2025-06-30

2025-07-04

2025-07-01