No spatter, extreme precision, more efficient, more stable and greener additive future

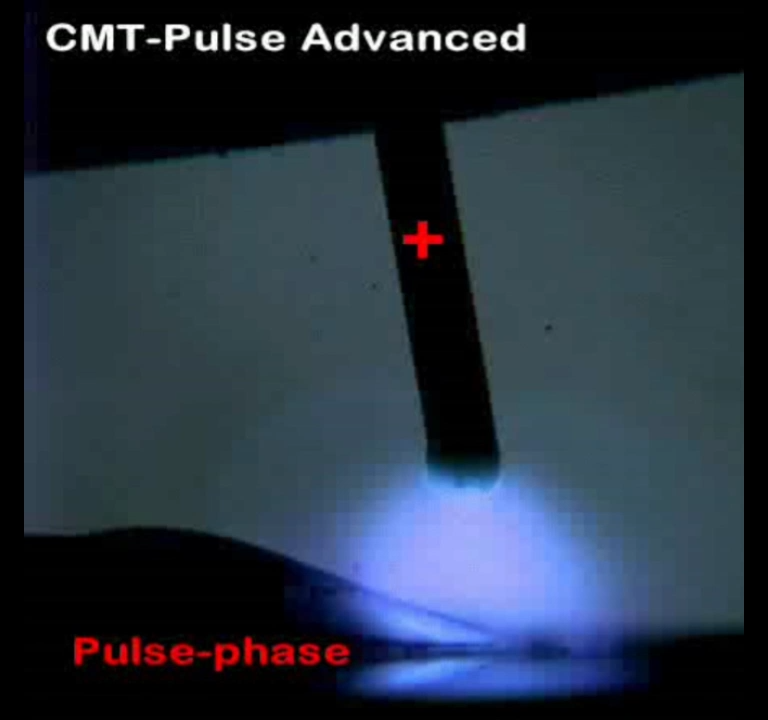

CMT (Cold Metal Transfer) is a new arc transfer process technology without spatter. Through the new droplet separation mechanism and fuse direction control, the deformation and spatter of the fuse process are significantly reduced. The principle is that during the arc generation process, the wire moves into the molten pool. At the moment of contact with the molten pool, the output current and voltage are reduced accordingly. This change triggers the wire to retract. The retraction action causes the droplet to separate and send the droplet into the molten pool. This not only ensures the precise deposition of the droplet, but also provides a cooling process for the molten pool, thereby optimizing the additive quality. At the same time, the wire continuously stirs the molten pool during this process, effectively suppressing defects such as pores and unfused molten pools.

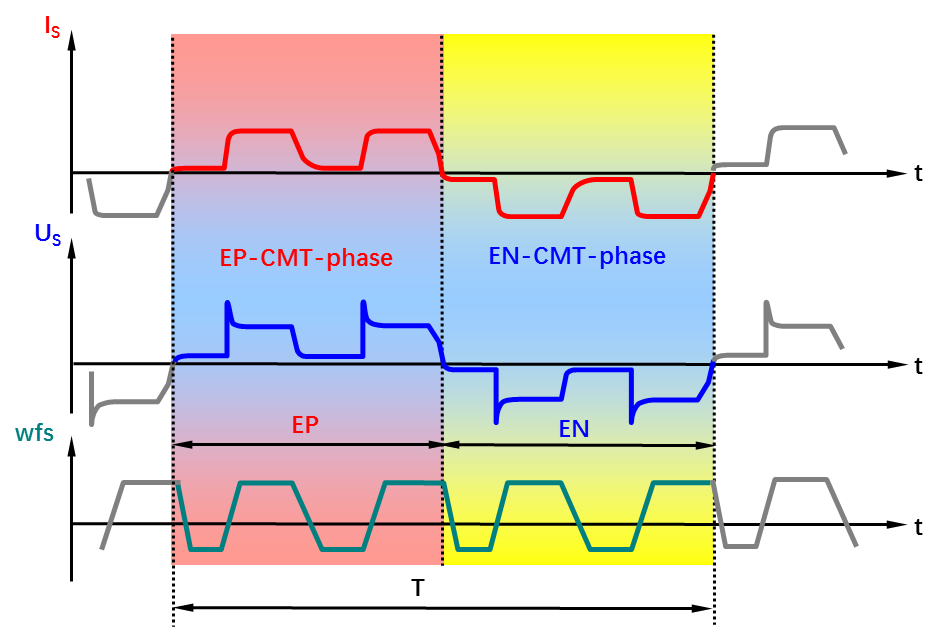

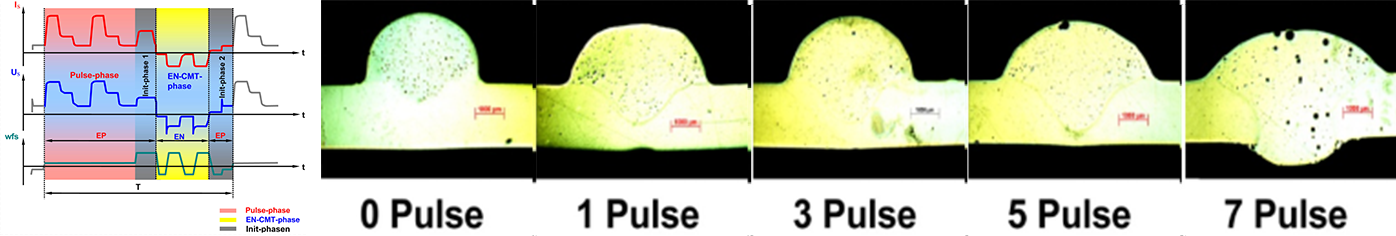

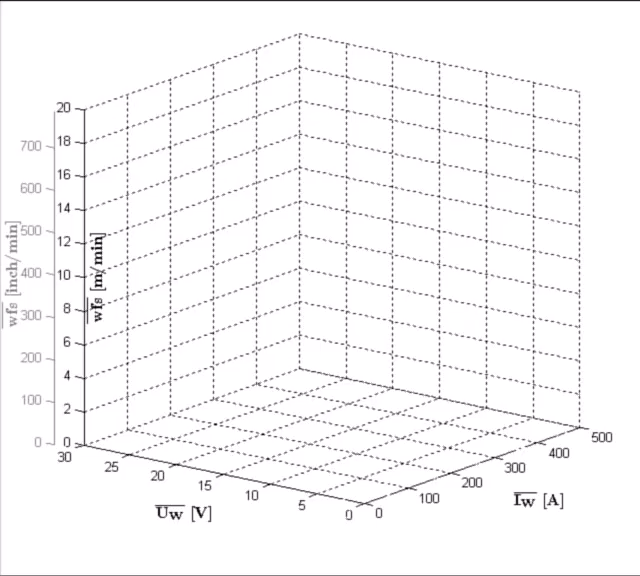

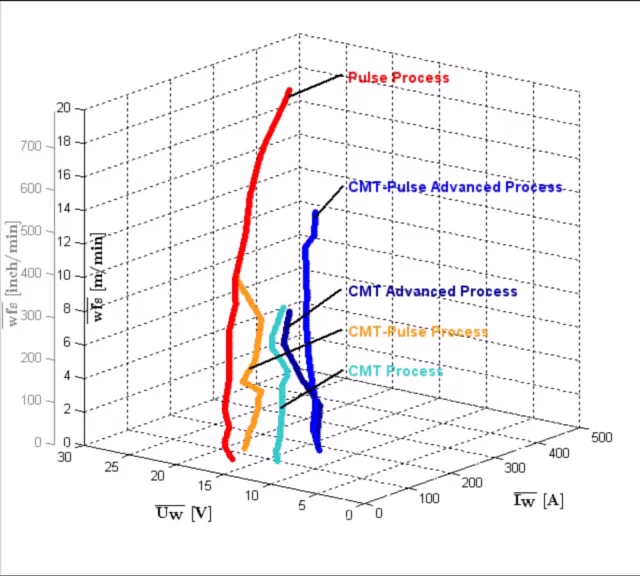

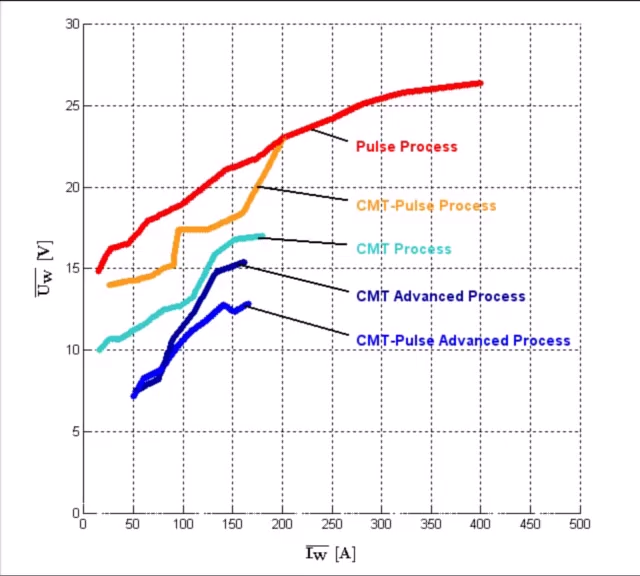

CMT Advanced AC/DC CMT is further developed on the basis of DC CMT technology. Through the intelligent transformation of current polarity, it achieves lower heat input and higher cladding efficiency. At the same time, by actively intervening in the droplet transition, innovative cold-hot alternating output is achieved, further improving the fuse efficiency and reducing heat input.