Nickel alloys play a vital role in modern industry due to their excellent high-temperature strength, corrosion resistance, oxidation resistance, and unique physical properties. Their main applications include aerospace, energy, shipbuilding, and automotive. This article primarily shares an analysis of the additive manufacturing capabilities of nickel alloy 718 using arc additive manufacturing processes.

01.Material Information

Material Form: Wire

Material Specification: φ1.2 mm

Model: Inconel 718

Features Overview: Inconel 718 is a mainstay of the aerospace industry. Its excellent heat resistance makes it ideal for high-temperature environments, including engine components. It is also used in high-performance automotive engines in the racing industry. Inconel 718 is a precipitation-hardening nickel-based superalloy with excellent toughness, fracture resistance, and corrosion resistance, and can be used at temperatures up to 1500°C.

02.Performance Indicators

| Condition | Temperature | Direction | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| AD-As Deposited | Room Temp | TD-Transverse | 771 | 455 | 21.3 |

| AD-As Deposited | Room Temp | BD-Longitudinal | 802 | 431 | 22.2 |

| HT-Heat Treated | Room Temp | TD-Transverse | 1405 | 1159 | 12 |

| HT-Heat Treated | Room Temp | BD-Longitudinal | 1449 | 1079 | 13 |

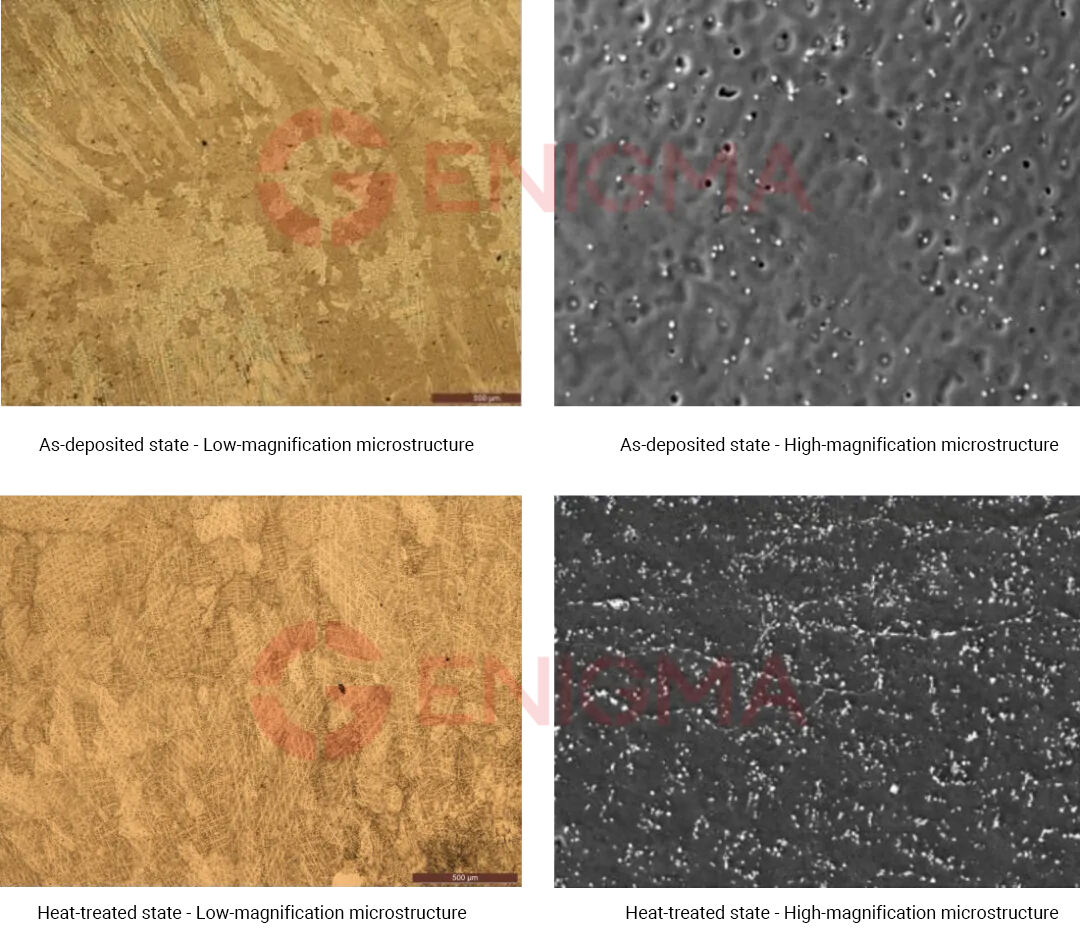

03.Microstructure

04.Composition Analysis

| Component Name | Pre-deposition Content (%) | Component Name | Pre-deposition Content (%) |

| Ni | 52.88 | Cu | 0.018 |

| Cr | 18.12 | Al | 0.06 |

| Mo | 3.04 | Co | 0.06 |

| C | 0.012 | Ti | 1.01 |

| Mn | 0.018 | B | 0.004 |

| Fe | 19.22 | others | < 0.5 |

| Si | 0.029 | Nb+Ta | 5.09 |

05.Additive Manufacturing Capability Analysis

Porosity Tendency: Has a certain porosity tendency. The alloy composition of SMC718 wire contains certain gaseous elements, such as nitrogen and oxygen. During the additive manufacturing process, these gaseous elements may dissolve in the deposited layer and cannot be released in time, forming pores.

Crack Sensitivity: The alloy composition of SMC718 wire contains certain elements such as nickel and chromium. These elements easily cause intergranular corrosion and precipitate formation during welding, thus increasing the tendency for cracking.

Flowability: Good flowability.

From "capable of manufacturing" to "manufacturing well," ENIGMA 's in-depth exploration and optimization of materials and processes in the DED additive manufacturing field is not only an upgrade of technical parameters, but also a leap from "quantity" to "quality." In the future, ENIGMA will continue to delve into the limits of additive materials and processes, explore larger-size and more efficient DED application scenarios, promote process standardization and intelligence, and empower a wider range of industrial applications.

Hot News

Hot News2025-06-30

2025-07-04

2025-07-01