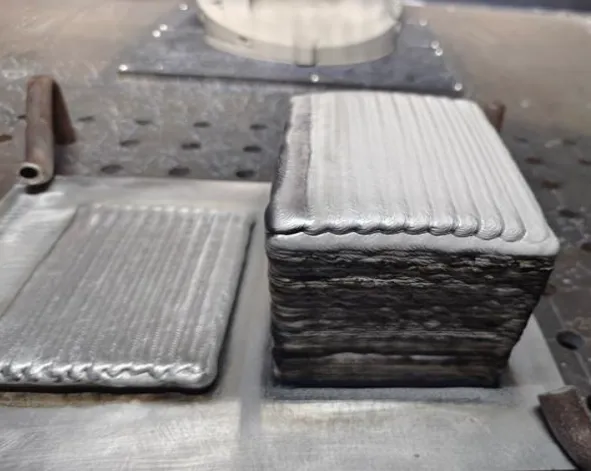

Aluminum alloy 2319 is a strengthenable aluminum alloy with aluminum and copper as the main alloying elements. It possesses high strength, good weldability, and corrosion resistance, exhibiting stability, especially at high temperatures, and is widely used in high-end manufacturing fields such as aerospace and military. This article mainly shares the additive manufacturing capability analysis of aluminum alloy 2319C using arc additive manufacturing.

01. Material Information

Material Form: Wire

Material Specification: φ1.2 mm

Model: ZL2319C

Features Overview: 2319 wire specially designed for arc additive manufacturing. The printed product from this wire exhibits higher strength and elongation after heat treatment, and fewer internal defects.

02. Performance Indicators

| Condition | Direction | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Vickers Hardness |

|---|---|---|---|---|---|

| AD-As Deposited | TD-Transverse | 290 | 149 | 15.2 | 77.7 |

| AD-As Deposited | BD-Longitudinal | 292 | 146 | 13.5 | 77.7 |

| HT-Heat Treated | TD-Transverse | 445 | 298 | 14.4 | 131.96 |

| HT-Heat Treated | BD-Longitudinal | 407 | 295 | 11 | 131.96 |

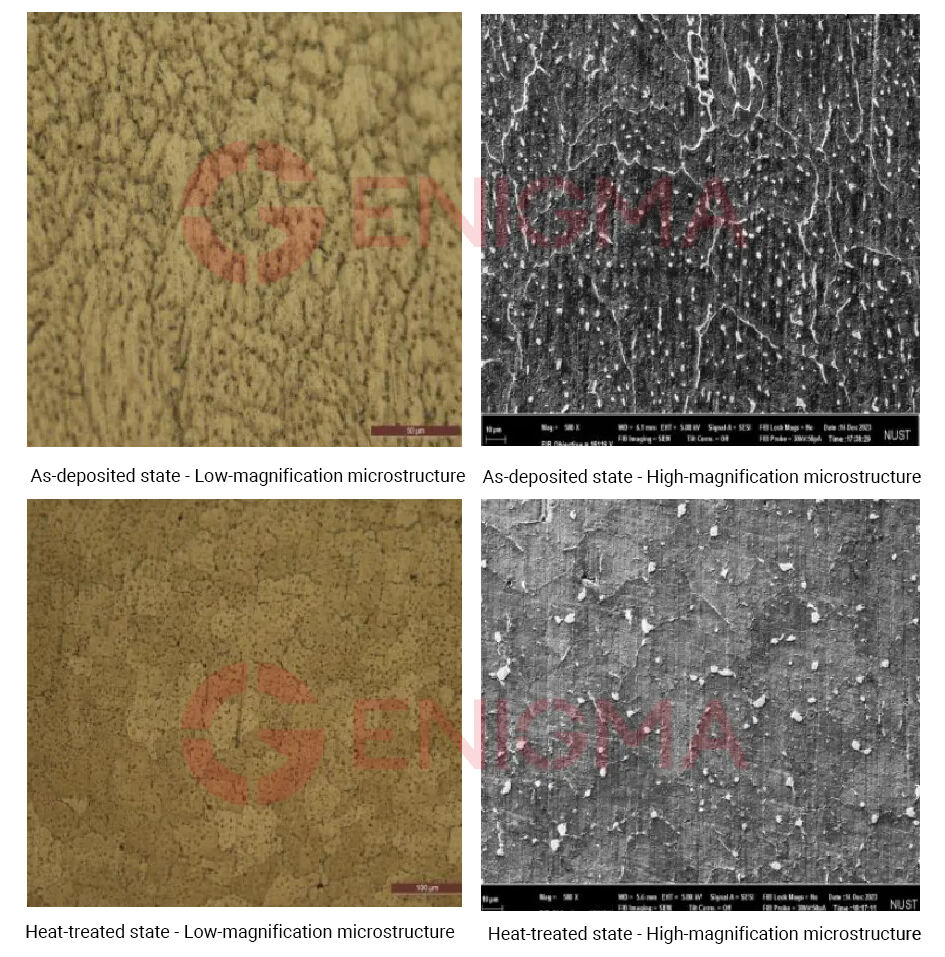

03. Microstructure

04. Composition Analysis

| Component Name | Pre-deposition Content (%) | Component Name | Post-deposition Content (%) |

| Cu | 5.3-5.8 | Cu | 5.74 |

| Fe | 0.3 | Fe | 0.14 |

| Mn | 0.2-0.4 | Mn | 0.28 |

| Si | 0.2 | Si | 0.049 |

| Zr | 0.1-0.25 | Zr | 0.23 |

| Mg | 0.02 | Mg | 0.005 |

| Ti | 0.02-0.15 | Ti | 0.11 |

| V | 0.05-0.15 | V | 0.15 |

| Al | Rem (Remainder) | Al | Rem (Remainder) |

05. Additive Manufacturing Capability Analysis

Porosity Tendency: Compared to cast aluminum alloys, arc additive manufacturing of 2319C has a lower probability of porosity. Porosity can be reduced by controlling the interpass temperature and increasing the wire feed speed.

Crack Sensitivity: 2319C aluminum alloy exhibits a certain degree of crack sensitivity during arc additive manufacturing. This material contains high levels of elements such as copper and nickel, which can easily induce hot cracks during welding. The high strength of this material, coupled with the significant stress generated during additive manufacturing, also contributes to cracking.

Flowability: Flowability is acceptable.

From "capable of manufacturing" to "quality manufacturing," Inigma's in-depth exploration and optimization of materials and processes in the DED additive manufacturing field represents not only an upgrade in technical parameters but also a leap from "quantity" to "quality." In the future, Inigma will continue to push the limits of additive materials and processes, exploring larger-scale and more efficient DED applications, promoting process standardization and intelligentization, and empowering a wider range of industrial applications.

Hot News

Hot News2025-06-30

2025-07-04

2025-07-01