Enigma Technology has become a primary innovator in the digital advancement of the manufacturing sector. The company’s IungoQMC Digital Intelligence System, the company’s primary product, leads the digital transformation of data-assisted decision-making within the sector. The IungoQMC system integrates, digitizes, and intelligently upgrades legacy manufacturing equipment. It functions as a centralized intelligent manufacturing hub and swivels the access of raw production data towards intelligent actionable decision-making. It offers tremendous versatility and can be focused on various processing equipment and methods (for instance, MIG/MAG, TIG, and plasma), laser, laser-arc hybrid welding, and various additive manufacturing processes, and can be customized further for other industrial application systems. In smart manufacturing, where the raw production data instead of the equipment has become the core of value creation, the IungoQMC does the heavy lifting of configuring production data into usable formats for decision-making. This makes the system an essential smart manufacturing solution for most industries where quality and productivity improvements are desirable.

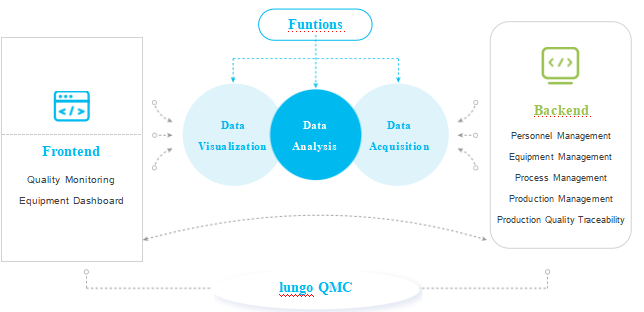

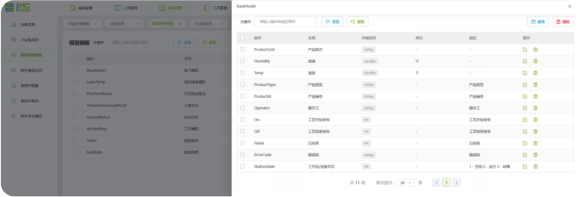

IungoQMC employs a highly customizable model for data acquisition, the starting point for all the system’s numerous capabilities.

This model can be modified to encapsulate the one-off needs of the various manufacturing equipment to make sure that there are no blind spots with the critical data. IungoQMC, operating together with the Derivative Box— a dedicated data collection device— obtains a variety of equipment and production process data, which includes digital, textual, image, video, and 3D point cloud data streams. After capture, the data is fed into a model built around the customized equipment data acquisition to be parsed in a structured manner to ensure consistency, accuracy, and safe storage in a time-series database. Accumulating information is only the start; this structured approach to data collection and storage prepares all key areas of manufacturing for integrated administrative control— personnel, equipment, consumables, processes, and output. IungoQMC removes data silos through centralization and organization of vast amounts of data to offer consolidated visibility of all manufacturing operations. This visibility is critical for insight-driven decision making, and it is only data that can provide this.

The extensive amount of data that is consolidated and organized in IungoQMC is the foundation for full production quality traceability; a non-negotiable element of exceptional manufacturing. IungoQMC achieves this through two primary functions to facilitate this traceability: online playback and offline playback.

With the online playback feature, manufacturing staff can immediately and synchronously track and review real-time production data. This lets them keep an eye on production processes and quickly pinpoint quality issues as they arise. The offline playback feature, however, enables teams to analyze and trace the quality of processes used in producing historical products. This helps them review cycles of past production to identify and analyze data to investigate quality issues that have emerged in the past. The combination of these two playback functions, along with the system's diverse data type storage and organization capability, guarantees traceability of each and every element of production, with equipment operation and material consumption at the top. The insights gained and the consistent quality of products tied to this traceability reveal process optimization opportunities, empowered by hindsight and data, to aid in the resolution of quality issues that arise in the future.

In IungoQMC, the functions of data collection and traceability are taken a step further to include real-time data analysis. This feature strengthens IungoQMC’s claim to supporting data-assisted decisions. The system employs sophisticated technologies in data analysis and artificial intelligence to analyze data on production and equipment in real-time as it is captured.

This real-time analysis examines processes and identifies patterns, trends, and risks that are not immediately obvious. For instance, the system enables real-time analysis of process parameters to capture early signs of equipment deterioration or defects to quality that allows early intervention. IungoQMC helps manufacturing teams adopt a more proactive approach to problem-solving by delivering insights derived from raw, real-time data. This approach improves operational efficiency and reduces the potential for costly errors by ensuring that operational decisions are made using the most current information available.

IungoQMC, at its core, data-assisted decision-making for manufacturing process alternatives. This, then, becomes the highest value output of the system by translating data collection, traceability, and real-time analysis into line of sight for control executives. For instance, the system improves workflow by using control data on equipment performance and production cycle times to identify and recommend changes to workflow steps that eliminate bottlenecks and enhance throughput.

IungoQMC's insights aid decision making regarding equipment maintenance, too: the system analyzes equipment data in real time to predict when maintenance will be necessary so that maintenance can be scheduled during downtime instead of unscheduled periods that force a halt to production. The system's contribution to enabling maintenance during scheduled downtime is invaluable. The system also helps decision-makers ensure that process outcomes are within the desired quality standards. By analyzing the value of process parameters and the quality of outcomes, decision-makers can adjust parameters to improve quality outcomes consistently. Process parameters include welding parameters, which can be adjusted to improve joint strength, and the materials used, which can be optimized to minimize waste. Each process IungoQMC deals with is data driven; this helps reinforce, ensure, and improve the reliability, consistency, and alignment of the outcomes with business objectives.

IungoQMC, powered by Enigma Technology, makes an invaluable contribution to decision making in the manufacturing sector through the transformative use of data. The closed loop of data-driven improvement IungoQMC engineered stems from end-to-end capabilities: the Derivative Box's customizable massive data acquisition, real-time data assessment, quality traceability, and process decision support. IungoQMC assists conventional manufacturing facilities in making a shift to smart, high quality, high efficiency operations by closing data silos, converting raw data to actionable insights, and facilitating proactive decision making.

Working with intelligent manufacturing equipment boosts daily efficiency and helps manufacturers meet changing industry needs. IungoQMC illustrates industry-leading data technology to present the competitive edge of answering data-driven questions and using information as a business tool. For manufacturers interested in smart manufacturing, IungoQMC isn’t simply a system; it is a transformative tool for integrating smart, data-driven efficiencies into process decision construction and implementation.

Hot News

Hot News2025-06-30

2025-07-04

2025-07-01