The Importance of Ded Powder Metal Additive Manufacturing

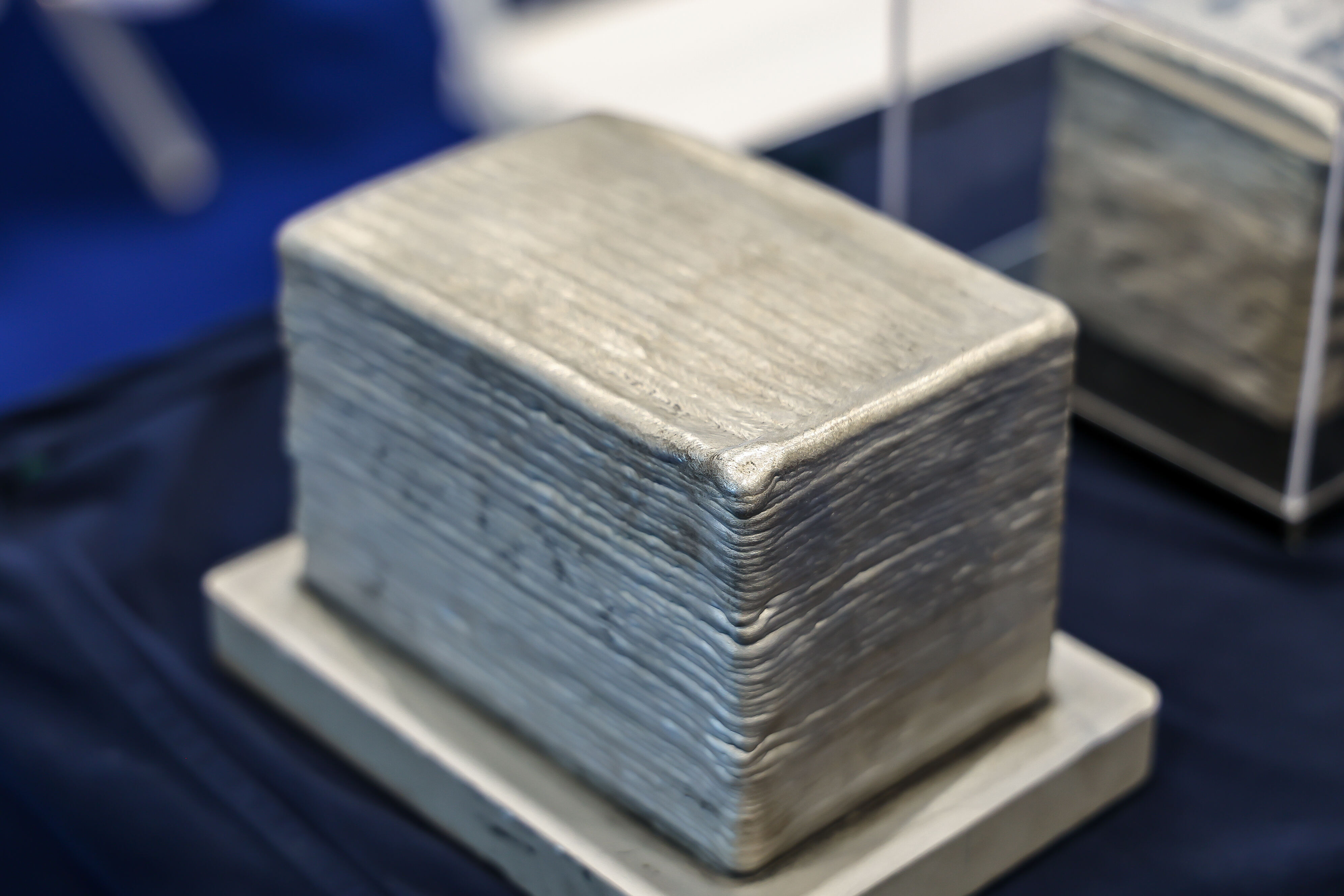

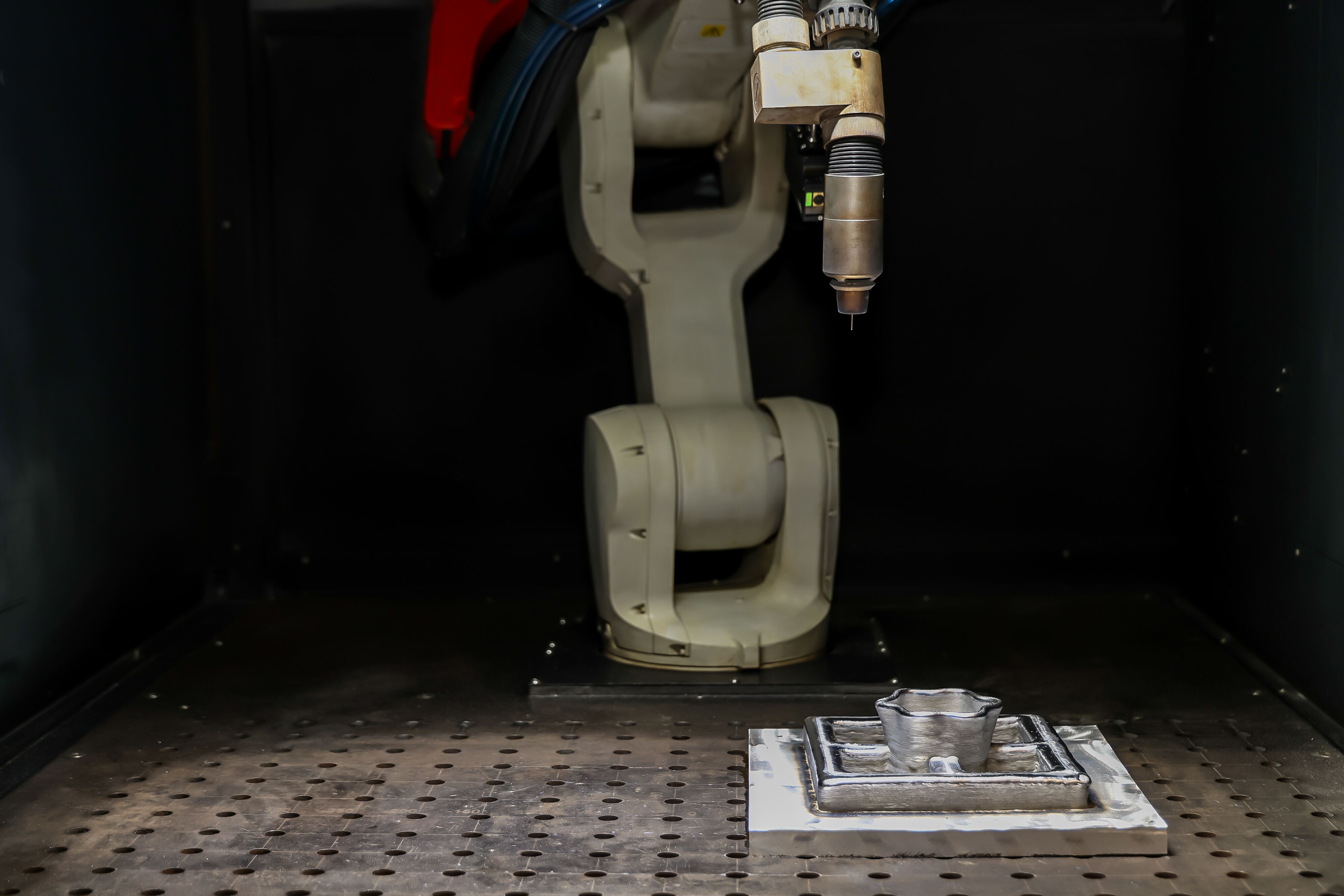

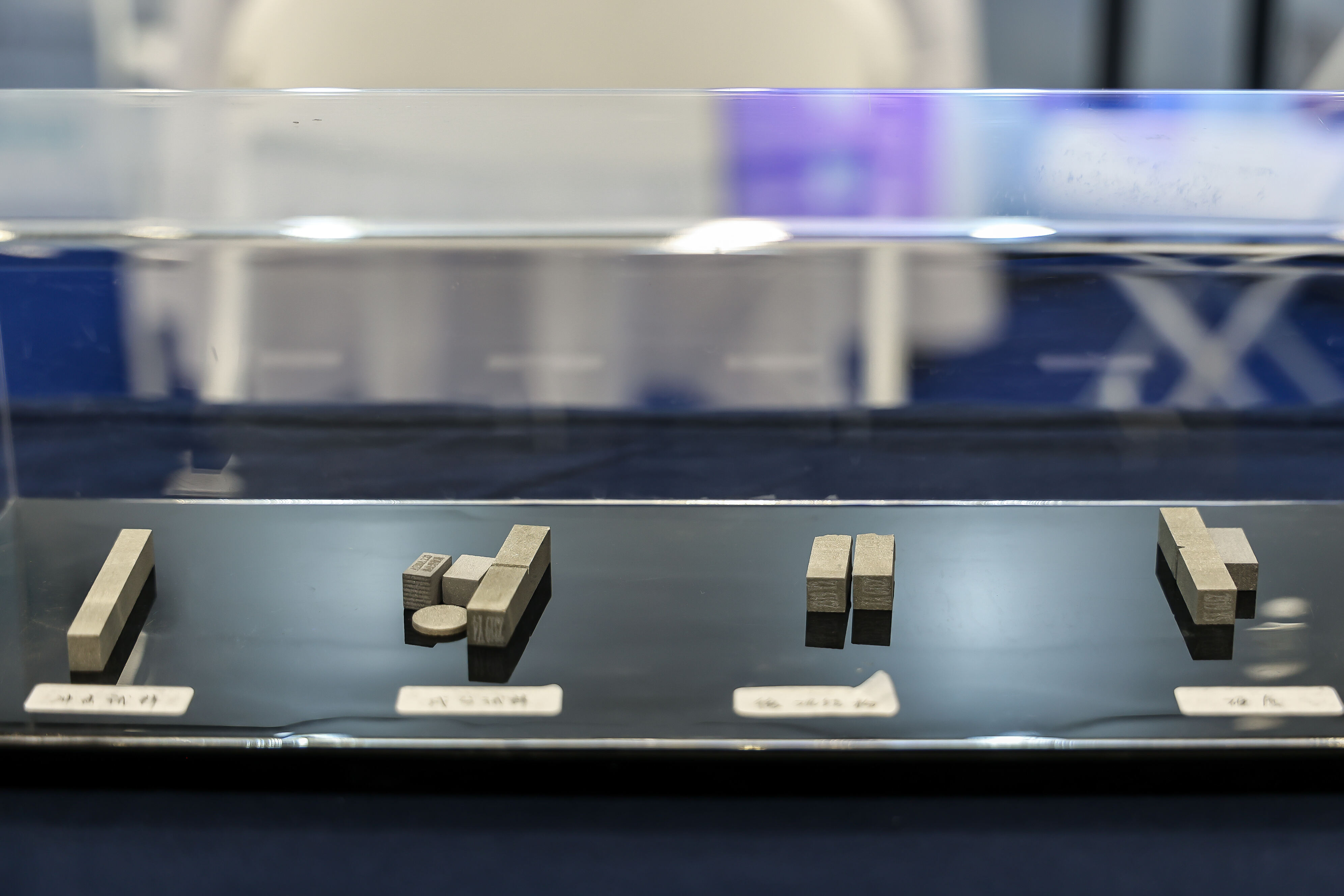

In the world of metal additive manufacturing, the precision of the quality control Ded Powder is vital. Nanjing Enigma Automation Co. Ltd uses modern technology to make Ded Powder that meets the standard specifications of various industries. Our enhancements make manufacturing processes more efficient, minimize waste, and optimize the mechanical properties of the end products. We focus on innovative and customer-driven solutions to help intelligent manufacturing meet the needs of the customers.